insights

Top-down vs. Bottom-up Inventory Planning: Which Strategy is Right for Your Brand?

Growing as a DTC brand doesn't just depend on winning new shoppers — it hinges on your ability to predict and meet customer demand, even as you scale. The way to do this is through strategic inventory planning.

To craft an inventory strategy, brands need to pick a methodology for their forecasting. While most opt for one of the two most common approaches — top-down or bottom-up planning — the choice isn't all black and white.

Both options offer attractive benefits that can supercharge business growth. Often, the winning move is finding the right balance between the two, where your brand has enough insights to scale sustainably without draining resources or diverting time from other initiatives.

This comprehensive guide will walk you through both methods to create a strategy that's truly tailored to your needs.

What is Inventory Planning?

Inventory planning is the process of calculating, reordering, and managing your stock quantities. It helps you replenish the right amount of units to capture every sales opportunity while avoiding excess items that tie up unnecessary cash. Done effectively, it's a powerful lever to drive profitability, helping you:

- Minimize stockouts and overstocks: By knowing how quickly your items sell over time and across channels, you can determine how much inventory to order and when (so you can meet demand without overstocking).

- Reduce carrying costs: Planning purchase orders with greater accuracy helps you avoid stocking up on unsellable items that rack up storage costs — ultimately lifting your bottom line.

- Enhance cash flow: Proper inventory planning prevents you from overselling without sufficient units to meet demand, enhancing your capital flow. This way, you avoid rush-ordering certain items at a higher cost because you've stocked out unexpectedly — giving you more money to fuel growth.

- Boost customer satisfaction: Keeping customers' favorite items in stock cements your brand's reliability and encourages them to return. Plus, you can reinvest the cash you've saved into your shopping experience with special perks like faster shipping or premium packaging.

Even small inventory planning initiatives — like stock counts and calculating minimum inventory levels — will lift up your business through more strategic purchasing decisions. But, to fully reap these benefits, you must understand the ins and outs of each distinct planning approach.

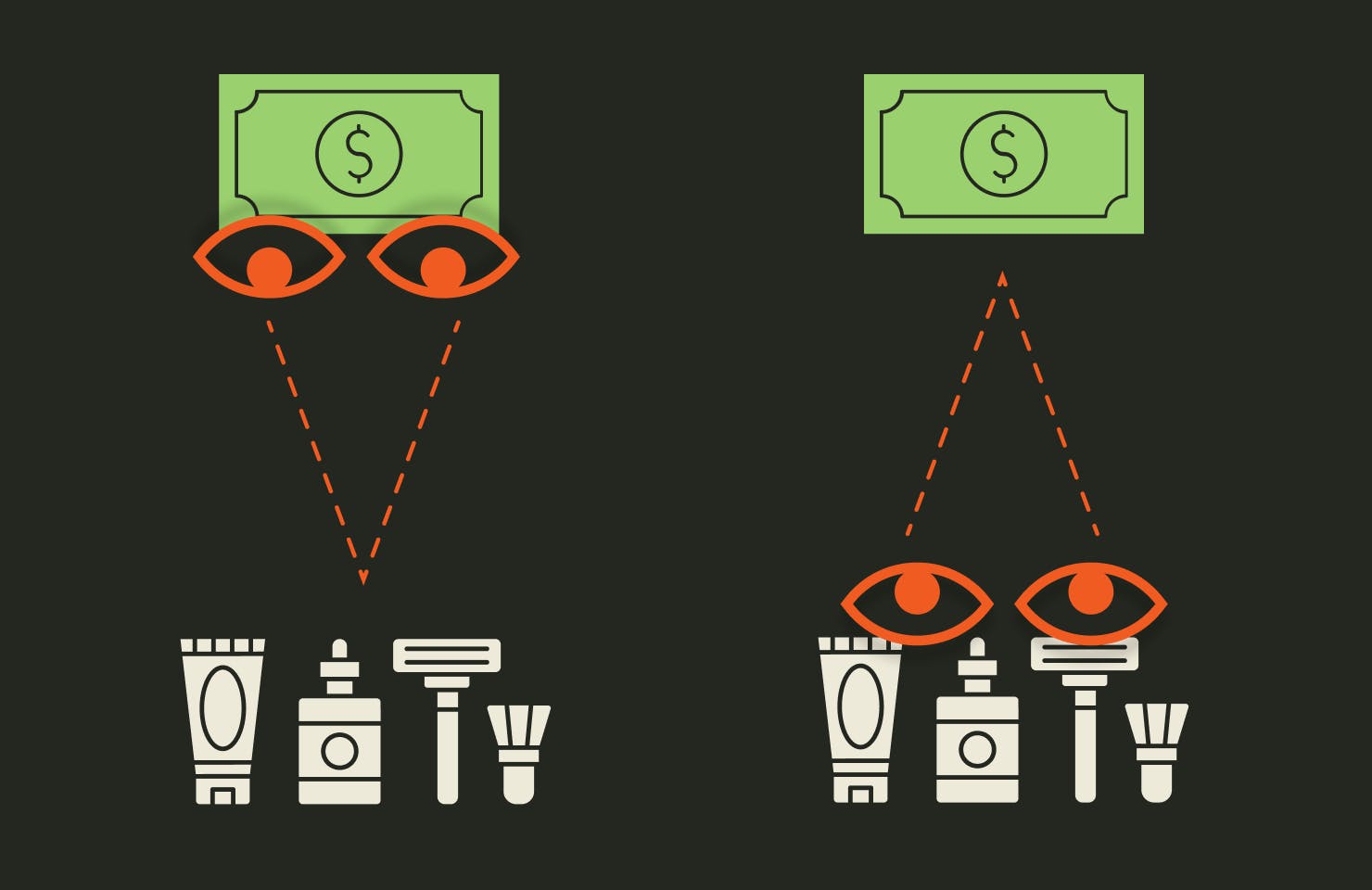

What is Top-down Inventory Planning?

Top-down inventory planning starts with your revenue goals. With a clear, high-level objective in mind, you can reverse-engineer how much inventory you need from each item to achieve it.

Say your coat brand made $2M in revenue last year and wants to reach $5M this year. To create a top-down inventory plan that meets this goal, calculate the contribution of each SKU to your current revenue (or reach out to your sales team for this data). If a wool coat costs $1,000 and last year's sales generated $200,000, it represents 10% of your total revenue.

Following this logic, the coat must bring $500,000 in the new year (10% of $5M) to support your financial objectives. At the $1,000 price point, you'd then order 500 units ($500,000 divided by $1,000) to reach your new goal. Applying this calculation across your product line, you can build a top-down inventory plan that fully aligns with your growth targets.

While you can crunch these numbers by hand, the process can quickly spiral. Automated inventory management tools like Moselle are designed to handle the math for you, accelerating your planning timeline while eliminating the potential for error across high-stakes calculations.

Benefits and Limitations of the Top-down Approach

Top-down forecasting streamlines your inventory operations with a plan tied directly to your revenue targets — offering quick insights to support decisions across departments like marketing, sales, and finance. Since it doesn't rely on analyzing product dynamics, brands can also project inventory counts for items with limited historical data.

The straightforward nature of top-down inventory planning makes it attractive for businesses that want to create swift, actionable plans for their teams. However, it can be difficult to forecast inventory for SKUs with volatile seasonal dynamics or respond effectively to early signals of surging demand.

Top-down inventory planning can be highly efficient for any DTC brand looking to optimize stock levels — especially those in the first few months of operation or with consistent purchasing patterns (like furniture and home goods).

For brands still accumulating sales and inventory data or working off predictable numbers, top-down planning lays a foundation to fuel their growth journey with informed replenishment decisions.

What is Bottom-up Inventory Planning?

In contrast to the top-down methodology, bottom-up planning begins with your inventory needs. Your operators first analyze historical sales, trends, and seasonal patterns for every demand forecasting unit (AKA, each product across every channel). Individual forecasts are then aggregated to project demand and revenue for the year ahead.

Let's say a sunglass brand wants to predict the number of units they'll need for a cat-eye model in January. Sales data from previous years determines they'll need 1,000 units to meet demand. However, further analysis revealed a 30% increase in sales over the past two months.

Knowing this, the brand projects that instead of the original 1,000 units, they should replenish 1,030 units. Repeating this process for every SKU would show how many units they need on hand for every sunglass model and how much total revenue they'd generate.

To fast-track your calculations, plug these figures into a fully automated inventory management platform to handle the heavy lifting with the utmost speed and accuracy.

Benefits of the Bottom-up Approach

Bottom-up inventory planning captures granular product performance information for a comprehensive inventory forecast. With this approach, you can identify high-demand products that need priority restocking and calculate expected revenue to guide both your budget and growth strategy.

The accuracy of bottom-up forecasting helps businesses plan operations months ahead. The trade-off? It requires detailed, current data for every SKU and significant time and effort from your team.

Bottom-up planning is particularly valuable for brands with complex inventory dynamics (like those selling T-shirts in multiple sizes and colors) and high seasonality (such as makeup and apparel).

However, even if your brand doesn't fall into these categories, bottom-up forecasts are most effective for validating and refining your top-down inventory strategy based on actual stock dynamics.

Top-down vs Bottom-up: Which is Best for Your Business?

By understanding the strengths and limitations of both inventory planning methods, brands can strike the right balance between the two and craft a strategy that suits their needs.

How to Use the Two Inventory Planning Approaches in Tandem

No inventory planning method can perfectly predict future demand. But pairing your high-level, sales-driven plan with granular historical data is the key to building a complete, nuanced inventory forecast for your business. Here's how:

- Start by building a top-down forecast based on your sales goals

- Perform a bottom-up analysis using your inventory records

- Compare the two forecasts in a shared system or document

- Create a master forecast that balances your growth targets with product-specific nuances

This approach will provide deeper insights into your inventory needs and help prevent stockouts and excess stock. And with a comprehensive inventory platform, you can effectively streamline the entire process.

The right tool will automatically process your historical sales data and consider your growth targets — so you can effortlessly reconcile both forecasts into a single, intuitive platform.

Supercharge Your Inventory Planning with Moselle

Moselle is the ultimate inventory forecasting solution for growing DTC brands seeking to drive profitability through optimal inventory levels. By connecting your data streams (like your sales channels and 3PL portal) to the platform, you can build and compare inventory plans following each methodology using Moselle’s powerful ML capabilities.

The process is seamless, creating a 360-view of your inventory needs for months in advance — all in a matter of seconds.

- On Moselle's Planning Page, select Create Plan to begin a new forecast.

- You can generate a projection for your plan using the top-down option and your AI model of choice (or create separate files to explore each).

- Select Edit Top-Down Targets from the Automate drop-down menu to enter your gross sales data in the Goals Table.

- Then, click Generate Bottom-Up Unit Forecast to see the converted unit forecast.

Following this process in Moselle, Fable consistently pulls sophisticated forecasts that span all business areas — eCommerce, retail, and B2B. As a result, the brand now meets their growing demand across channels and audiences, generating significant wins in the process:

- $120,000 annual savings

- 80 hours saved per month on forecasting and planning tasks

- Only a 10% variance between recent and actual forecasts

Moselle Fuels Business Growth with Robust Inventory Forecasting

With Moselle, you can run precise top-down and bottom-up inventory plans on demand — and act on them in seconds.

Ready to revolutionize your inventory planning? Get started today.